Vitrification 101

The Vit Plant will use proven vitrification technology to stabilize Hanford’s radioactive waste. Vitrification has been successfully used at waste processing sites in the United States and around the world. A few of these sites include the following:

- Savannah River Site in South Carolina

- West Valley Demonstration Project in New York

- Sellafield Site in the United Kingdom.

Vitrification has not, however, been used to the scale or on waste as complex as the waste at the Hanford Site.

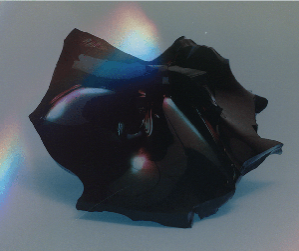

Vitrification involves mixing waste with glass-forming materials, heating it at high temperatures, and pouring it into stainless steel containers to cool and solidify. In this glass form, the environmental risks are eliminated, and the waste is stable and safe for permanent disposal.

Vitrification involves mixing waste with glass-forming materials, heating it at high temperatures, and pouring it into stainless steel containers to cool and solidify. In this glass form, the environmental risks are eliminated, and the waste is stable and safe for permanent disposal.

While most standard household glass is soda lime glass, the Vit Plant will produce borosilicate glass like other vitrification plants. Borosilicate glass’s primary constituents are silica and boron oxide, which allows for higher waste loading and is not prone to groundwater leaching.

- At the Vit Plant, low-activity waste will be transferred via underground pipelines from the Hanford Tank Farms to the Low-Activity Waste (LAW) Facility at the Vit Plant.

- At the LAW Facility, the waste will be mixed with 12 glass-forming materials, all which are mined minerals used in other glass manufacturing. They include the following:

- aluminum silicate

- boric acid

- borax

- calcium silicate

- ferric oxide

- lithium carbonate

- magnesium silicate

- silica

- sodium carbonate

- sucrose

- titanium dioxide

- zinc oxide

- zirconium silicate.

- The low-activity waste will use combinations of 11 out of the 12 glass-forming chemicals stored on site. Each batch will contain about 50 percent silica, the primary glass-making ingredient.

- The waste mixture will be heated to 2,100 degrees Fahrenheit in the massive 300-ton low-activity waste melters.

- The mixture will be poured into stainless steel containers to cool and solidify.

- The containers will be transferred for permanent storage on the Hanford Site.

The low-activity waste will be disposed of at the Integrated Disposal Facility on the Hanford Site. The high-level waste will be temporarily stored at a canister storage facility on the Hanford Site before being shipped to a national repository.

As part of its Direct-Feed Low-Activity Waste (DFLAW) approach, DOE will focus on treating the low-activity waste, the majority of Hanford’s waste, first. Bechtel National, Inc., its partners, and DOE are now completing the final steps for DFLAW to begin vitrification in 2025.

Both engineering and construction work continue on the High-Level Waste Facility. The high-level waste will be processed at a later date.