Workers complete assembly of 300-ton nuclear waste melter at Hanford Vit Plant

ORP and Bechtel announce employees have safely completed final assembly of the first melter at the Vit Plant.

Achievement marks U.S. largest vitrification equipment of its kind

RICHLAND, Wash. —The Department of Energy’s Office of River Protection (ORP) and contractor Bechtel National Inc. (BNI) today announced employees have safely completed final assembly of the first melter at Hanford’s Waste Treatment and Immobilization Plant (WTP), also known as the Vit Plant. The 300-ton nuclear waste melter is one of two located inside the WTP’s Low-Activity Waste (LAW) facility.

“The melters are the heart of the WTP low-activity waste vitrification process, and completing the assembly marks another step towards completing construction and shifting to commissioning. The melters are large complex pieces of equipment critical to WTP’s success,” said Bill Hamel, WTP Federal Project Director for the ORP.

Construction crews are now focused on safely assembling the second LAW melter.

“The melter final assembly brings us one step closer to Low-Activity Waste facility construction completion,” said Peggy McCullough, BNI project director for the WTP Project. “For our employees, this achievement represents a substantial, detailed design, fabrication and assembly effort for the largest nuclear waste melter ever built in the U.S.”

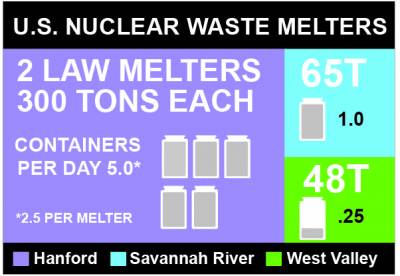

The melters will be used to heat Hanford’s low-activity tank waste and glass-forming materials to 2,100 degrees Fahrenheit – a process called vitrification – before the mixture is poured into stainless steel containers for permanent storage. During plant operations the two LAW facility melters will produce 30 tons of glass daily, ten times the capacity of the melter in operation at DOE Savannah River Site's Defense Waste Processing Facility in South Carolina.

The LAW facility melters, and other components of the facility, can be seen in the Vit Plant Virtual Tour.

BNI holds the prime contract to design, construct, start up and commission the Vit Plant, which includes the LAW facility, an Analytical Laboratory, the High-Level Waste (HLW) facility, the Pretreatment (PT) facility and a collection of more than 20 support facilities. The LAW facility, Analytical Laboratory and set of support facilities are part of DOE’s Direct Feed Low-Activity Waste approach to treat low-activity tank waste as soon as 2022, and ahead of full WTP commissioning, taking advantage of those facilities that are close to completion.

About the Office of River Protection

The U.S. Department of Energy's (DOE) Hanford Site in southeast Washington state is home to 56 million gallons of chemical and radioactive waste stored in underground tanks – the result of more than four decades of plutonium production. The Office of River Protection (ORP) is responsible for the retrieval, treatment, and disposal of this waste in a safe, efficient manner. The River Protection Project is the largest and most complex environmental remediation project in the nation.

About Bechtel

Bechtel is designing and building the world’s largest radioactive waste treatment plant for the DOE at the Hanford Site in southeastern Washington state. The Waste Treatment and Immobilization Plant, also known as the Vit Plant, will immobilize the millions of gallons of radioactive liquid waste stored in 177 underground tanks using a process called vitrification. Visit www.hanfordvitplant.com.

###

High-Resolution Download: Right-click on a photo and select "Save Link As" or click on a photo to open a high-resolution version, then right-click the photo and select "Save Picture As."

Aerial of the Low-Activity Waste (LAW) Facility. The LAW Facility will turn low-activity radioactive and chemical waste into glass to be permanently stored at Hanford.

In 2012, a Low-Activity Waste Facility melter is pulled out of the building on rails for inspection. The melter will be one of two used to heat Hanford’s underground low-activity tank waste and glass-forming materials to 2,100 degrees Fahrenheit before the mixture is poured into stainless steel containers for permanent storage in a process called vitrification.

In 2014, workers install refractory brick inside a Low-Activity Waste (LAW) Vitrification Facility melter. During operations the refractory brick will provide thermal insulation and structural support for the melter.

During operations the Low-Activity Waste (LAW) Facility’s two melters will produce 30 tons of glass daily, ten times the capacity of the melter in operation at the Department of Energy Savannah River Site's Defense Waste Processing Facility in South Carolina.