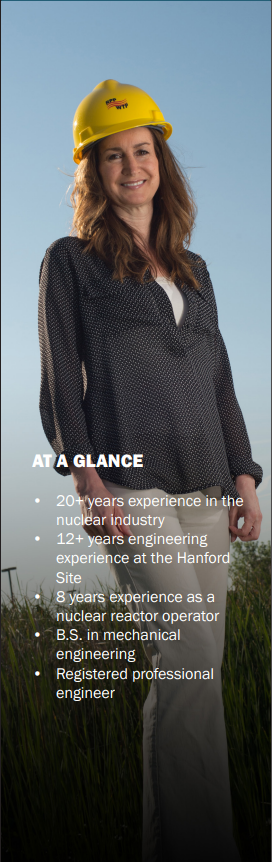

Sarah has more than 20 years of experience in the nuclear industry, including eight years working as a nuclear reactor operator. She worked at both a Department of Energy test reactor and an operating nuclear power plant.

“It was really fun,” Sarah says. “As a reactor operator, I learned about systems and equipment and nuclear physics. I learned how to control the reactor by adjusting various components, like the fan speed. There are so many interconnecting pieces that I had to know how to control and bring them together so the reactor performed the way I wanted it to.”

Now, Sarah applies that experience and her degree in mechanical engineering to designing the Hanford Vit Plant, where she is the systems engineering manager. In this position, Sarah is responsible for managing the complex program that identifies, controls, and verifies achievement of the Vit Plant’s more than 11,000 technical requirements.

I know what it’s going to be like during operations, and I apply that knowledge when I approach the design.

Because of my experience as a reactor operator, I understand safety control designs and system operations.

When asked if she is confident in the Vit Plant design, she doesn’t hesitate before answering a definitive “yes.”

“We have the people and the processes to produce a quality design that will safely fulfill the Vit Plant mission.”

DID YOU SAY 11,000 REQUIREMENTS?

- Before it operates, the Vit Plant must meet, and prove it has met, more than 11,000 technical requirements from various sources, such as its contract; federal, state, and local laws; and DOE orders.

- These requirements ensure the plant operates safely by protecting workers, the public, and the environment.